- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Home

Home | About Us | Service | FAQ | Resources | Technical Knowledge | News | Contact Us

Home | About Us | Service | FAQ | Resources | Technical Knowledge | News | Contact Us

Views: 0 Author: Site Editor Publish Time: 2025-10-13 Origin: Site

When you ask, "what is plywood," you discover that it is a type of engineered wood created by pressing thin layers of wood, called veneers, together. This unique manufacturing process is what gives plywood its impressive strength and stability, setting it apart from other wood materials. People choose plywood for a variety of reasons:

It can support heavy loads and resists bending or breaking.

Plywood is easy to cut and shape for different projects.

It is suitable for both indoor and outdoor use because it withstands water and weather.

Plywood is affordable and widely available.

You'll often see plywood used in construction and furniture making because it is strong, flexible, and reliable.

Plywood is made by gluing thin wood layers together. These layers are called veneers. This makes plywood strong and stable.

The cross-grain structure stops plywood from warping or cracking. This makes it good for heavy loads and many projects.

Plywood is useful for many things. You can use it for building, furniture, or art. It works indoors and outdoors.

There are different kinds of plywood, like softwood and hardwood. Each type fits certain needs. Knowing the types helps you pick the best one.

Plywood does not cost much because of new ways to make it. It is strong and reliable but not expensive.

Plywood is not just a plain wood sheet. It has a special structure that makes it different. Manufacturers build plywood by stacking thin wood layers called veneers. Each layer's grain goes in a different direction than the one below. This cross-graining makes plywood strong and steady.

The cross-grain design helps plywood stand up to forces from many sides. This makes plywood great for tough jobs like roofing and flooring.

Solid wood is different from plywood. You can see the differences in the table below:

Feature | Plywood | Solid Wood |

|---|---|---|

Grain Direction | Changing grain direction stops warping and twisting | Same grain can warp or twist when stressed |

Load-Bearing Capacity | Handles bending and warping well | Not as strong for heavy loads |

Moisture Resistance | Made to resist moisture | Can warp in wet places |

Plywood comes in many thicknesses and numbers of layers. More layers mean more strength and different uses. Here is a simple guide:

Thickness (mm) | No. of Plies of Commercial Plywood |

|---|---|

2~3.2 | 3 |

3.6 | 3 or 5 |

4 | 5 |

5.2~6.5 | 5 or 7 |

9 | 7 or 9 |

12 | 9 or 11 |

15 | 11 or 13 |

18 | 13 or 15 |

21 | 15 or 17 |

24 | 17 or 19 |

27 | 19 or 21 |

Thicker plywood has more plies. This helps it hold more weight and stay strong.

What makes plywood special? Its main features are strength, stability, and flexibility. The layers spread weight out evenly. You can use plywood for floors, roofs, and furniture. It does not bend or crack easily.

Plywood's layers help spread weight.

It can hold heavy things without breaking.

Good for floors, roofs, and furniture.

Plywood also fights off moisture better than other wood panels. This makes it good for places with water or humidity. You can use plywood outside or in kitchens and bathrooms.

Plywood is made to keep out moisture. This stops it from coming apart or bending when wet. That makes it great for outdoor use and places with lots of humidity. It stays steadier than solid wood.

Plywood is better than MDF or particle board in many ways. Look at the table below to see the differences:

Material | Resistance to Warping and Cracking | Moisture Susceptibility | Durability |

|---|---|---|---|

Plywood | Best | Medium | High |

MDF | Medium | High | Medium |

Particle Board | Low | Very High | Low |

Plywood has special physical and mechanical features. These include how much water it takes in, how much it swells, how strong it bends, and how flexible it is. These things make plywood a good choice for many jobs.

If you want to know why plywood is popular, remember these points:

Strong and steady because of cross-graining.

Does not warp, crack, or soak up water easily.

Comes in many sizes and thicknesses.

Works for tough jobs and everyday projects.

Because of these features, plywood is a favorite for builders, woodworkers, and people who own homes.

Knowing how plywood is made helps you understand its strength. Factories today use special machines to make plywood quickly and well. The Mingding D Tech Plywood Production Line is one example. Let's look at the steps.

First, workers pick logs from many tree types. Some common trees are:

Oak

Maple

Birch

Pine

Spruce

Fir

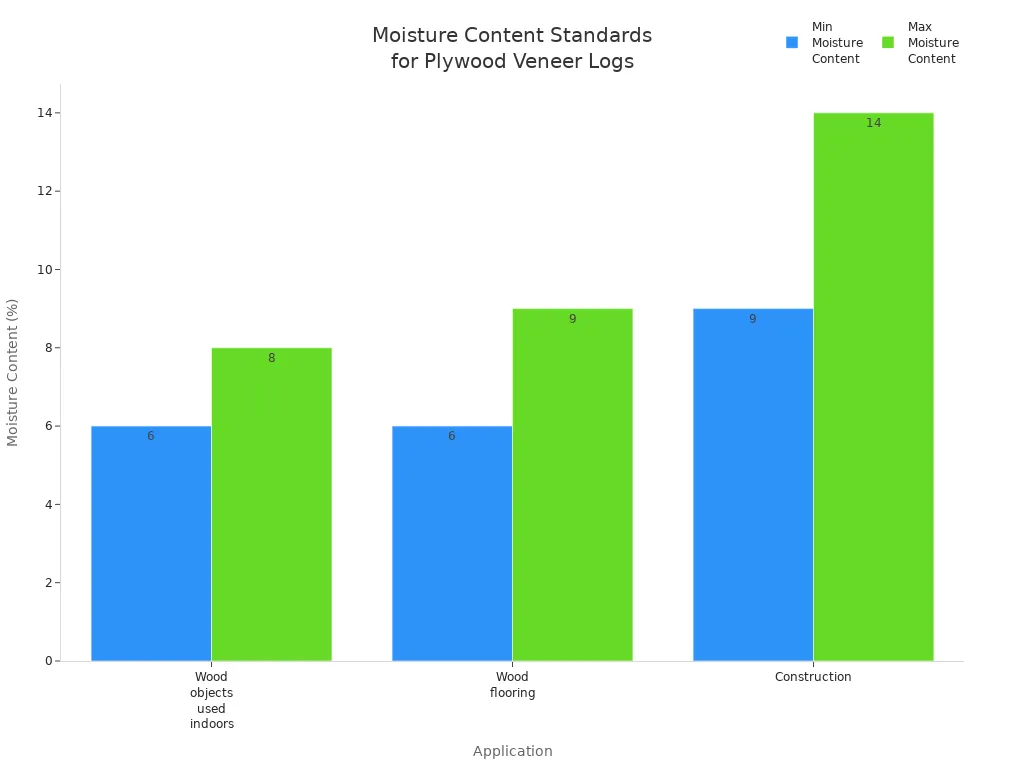

The logs must have the right amount of water inside. If logs are too wet or dry, problems can happen. Mold may grow, metal parts can rust, or the plywood may be weak. Here is a table that shows how much moisture is okay for different uses:

Application | Acceptable Moisture Content |

|---|---|

Wood objects used indoors | 6-8% |

Wood flooring | 6-9% |

Construction | 9-14% |

The Log Cutting Saw cuts the logs to the right size. Next, the Log Debarker takes off the bark. Now the logs are ready for the next step.

The amount of water in wood changes with the weather. For example, wood in Seattle has more water than wood in Las Vegas because of the climate.

After the logs are ready, it is time to make veneers. The veneer peeling machine slices the logs into thin sheets. These sheets are called veneers. Good veneers help make strong and nice-looking plywood.

There are different ways to cut veneers. Each way gives a different look to the wood grain:

Technique | Description | Grain Pattern |

|---|---|---|

Rotary | Slices around the log for wide sheets | Varied |

Flat | Makes straight cuts for pretty grain | Cathedral |

Quarter | Cuts log quarters for straight grain | Straight |

Rift | Angled cuts for a comb-like look | Linear, comb-like |

After cutting, the veneers must be dried. Hot air can dry them, or they can touch hot surfaces. Drying stops the wood from warping and keeps it strong.

The veneer composer puts the veneers together. It makes sure they fit well and have no spaces.

Next, glue is put on the veneers. The glue mixer makes the glue. The glue spreader covers each sheet with glue. The kind of glue is important. Some glues can let out chemicals like formaldehyde. Safer glues, like phenolic resins, are better for people and nature.

The veneer paving machine stacks the glued sheets in layers. Each layer's grain goes a different way. This makes plywood strong and steady.

Good glue helps plywood stay strong and resist water.

Strong glue keeps the layers together, even when wet.

Factories check the glue strength with tests like the Bonding Shear Test and Delamination Test.

Now, the layers are pressed together. The cold press machine squeezes them at room temperature. The hot press machine uses heat and pressure to bond the layers tight. This step makes the plywood tough and long-lasting.

Here are the usual hot pressing settings:

Parameter | Value |

|---|---|

Hot-pressing temperature | 120 °C |

Hot-pressing pressure | 1.2 MPa |

Hot-pressing time | 80 s mm−1 |

Hot pressing makes the glue soak deep into the wood. This step gives plywood its solid form.

After pressing, the edge trimming saw cuts the plywood to size. It also removes rough edges. The Sanding and Polishing Machine smooths the surface. Now the plywood is ready for paint or finish. These steps make plywood look and feel better. They also help paint and finishes stick well.

Sanding makes the surface smooth.

Edge trimming takes off splinters.

Edge banding and wood filler can make the edges look nicer.

Modern plywood lines, like Mingding D Tech, use smart machines. These machines help make strong plywood fast. You get good plywood for any project.

Now you know how plywood is made from logs into a useful building material.

There are many kinds of plywood for different jobs. Each kind has special features for certain uses. Knowing the types helps you pick the right one.

Softwood plywood comes from trees like pine, spruce, or fir. Builders use it a lot because it is light and easy to move. It works well for walls, roofs, and floors. You can also use it for crates and packing.

Here is a table that shows how softwood and hardwood plywood are different:

Property | Hardwood Plywood | Softwood Plywood |

|---|---|---|

Strength and Hardness | Stronger, harder, good for furniture and structure | Less strong, good for moderate load-bearing jobs |

Durability | Highly durable, resists dents and scratches | Moderately durable, may dent more easily |

Weight | Heavier and stable | Lighter, easy to move |

Appearance | Attractive grain, good for visible surfaces | Less grain, often covered or painted |

Cost | More expensive | More affordable |

Workability | Harder to work with | Easier to cut and shape |

Moisture Resistance | Varies by species | Varies by species |

Hardwood plywood is made from trees like oak, maple, or birch. People use it for furniture, cabinets, and musical instruments. It is strong, steady, and looks nice. This type is good when you want both strength and beauty.

You can use hardwood plywood for:

Fancy furniture and cabinets

Wall panels that look warm

Musical instruments

Hardwood plywood costs more money, but it lasts longer and looks better. If you need something tough and pretty, this is a good choice.

Some plywood types are made for special jobs. These include marine, exterior, subfloor, and aircraft plywood. Each one has its own use.

Plywood Type | Unique Properties and Uses |

|---|---|

Exterior Sheathing | Moisture-resistant, used for walls and roofing |

Subfloor | Thick, water-resistant, tight fit for floors |

Marine | Waterproof glue, resists water damage, great for boats and outdoor use |

Aircraft | High-strength, lightweight, used in planes and special projects |

You might use specialty plywood for:

Marine plywood: Outdoor benches, gazebos, or boat parts

Subfloor plywood: Strong, water-resistant floors

Exterior sheathing: Building walls and roofs

Aircraft plywood: Projects that need light but strong wood

When you know the types of plywood, you can choose the best one. Each type has its own benefits, so you can always find a good match for your project.

If you ask what plywood is used for, there are many answers. Plywood is found in many places around you. You see it in buildings, furniture, and art projects. Let's look at where plywood is most useful.

You might wonder how plywood is used in building things. Builders like plywood because it is strong and simple to use. Almost half of all plywood made is used in construction. You can find plywood in walls, roofs, and floors. It helps buildings stay safe and strong.

Here are some ways plywood is used in construction:

Application Type | Description |

|---|---|

Panel Siding | Plywood covers the outside of walls. |

Roof Sheathing | Plywood is a main part of roof sheathing. |

Structural Diaphragms | Plywood makes buildings more stable as diaphragms. |

Standards Compliance | Plywood must follow RS 10-54 and RS 10-56 rules in codes. |

Plywood can hold heavy weight and does not bend easily. It is trusted for safe homes and schools.

You may ask how plywood is used for furniture. Plywood is popular for tables, chairs, cabinets, and shelves. It looks like real wood and holds screws well. Most plywood does not have formaldehyde, so it is safe at home.

Here is a table that shows how plywood compares to other materials:

Material | Advantages | Disadvantages |

|---|---|---|

Plywood | Very strong, looks like wood, resists water, holds screws well | Can cost more than MDF |

MDF | Smooth surface, good for painting, cheaper for inside use | Not as strong as plywood, not good with water |

Solid Wood | Looks natural, strong and tough | Can bend or crack, costs more |

When you pick plywood for furniture, you get both strength and style. Plywood is used to make cabinets that last, shelves that do not bend, and desks that stay steady.

You might still wonder how plywood is used outside of buildings and furniture. Plywood is flexible and can be used in many ways. It is found in car interiors and boats. Factories use plywood for pallets, crates, and shelves.

Here are more ways plywood is used:

Cool home decor like candle holders and shelves

Everyday items such as bike racks and planter boxes

Covering buildings to make them look better and save energy

Modular building, which cuts waste by half

Green roofs that help plants grow and help nature

Art projects like wall art, sculptures, and displays

Artists like plywood because it is easy to cut and shape. You can make many beautiful and useful things with it.

When you ask what plywood is used for, you see it works for almost any project. Builders, designers, and artists keep finding new uses for plywood every day.

Plywood is very strong. It has many layers. Each layer's grain goes a different way. This stops the panel from splitting. It also keeps it from bending or cracking. The cross-grain design helps plywood hold heavy things. Plywood does not warp like solid wood. Strong glue spreads weight across the sheet.

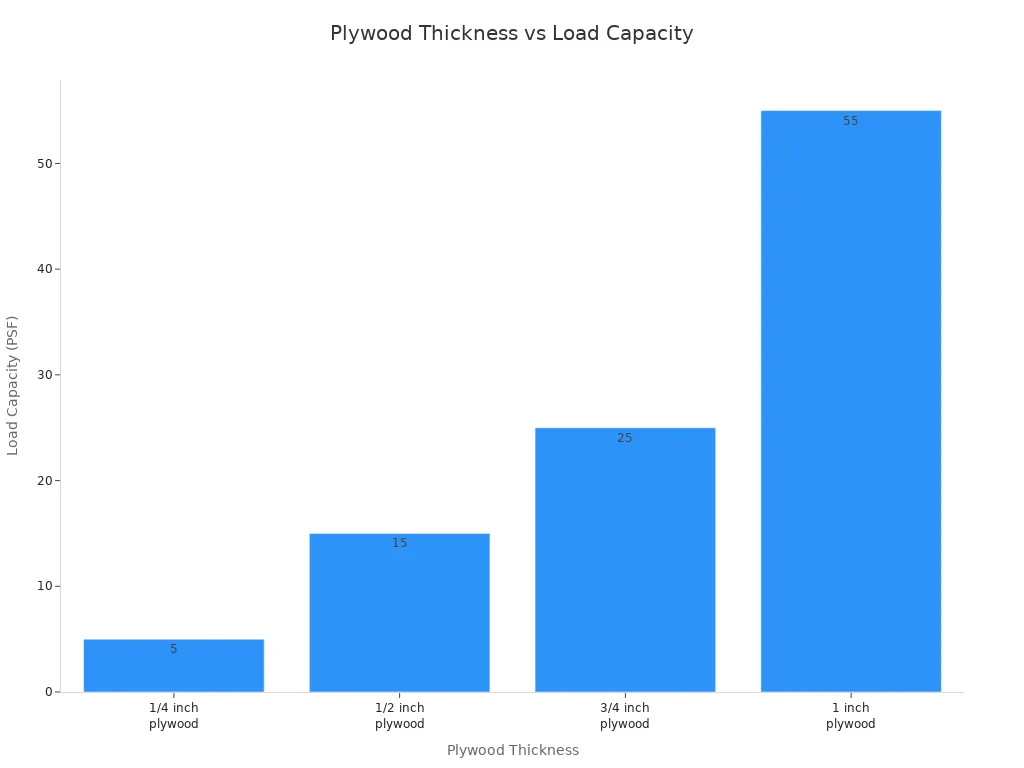

Here is a table that shows how much weight plywood can hold:

Plywood Thickness | Approximate Load Capacity (PSF) | Common Applications |

|---|---|---|

1/4 inch plywood | ~ 5 PSF | Decorative panels, drawer bottoms, lightweight backing |

1/2 inch plywood | ~ 15 PSF | Light shelving, basic cabinetry, wall sheathing |

3/4 inch plywood | ~ 25 PSF | Heavy-duty shelving, subflooring, workbenches |

1 inch plywood | ~ 55 PSF | Industrial shelving, heavy-duty work surfaces, platforms |

Exterior plywood is built strong. It works well outside. It can handle bad weather and lots of use.

Plywood is useful for many things. It is strong and bends easily. The cross-graining lets plywood bend without breaking. This makes it good for curved shapes and special furniture. You can use exterior plywood for boats or benches. It needs to be both strong and flexible.

Plywood's layers make it tough and steady.

The grain direction helps stop splitting.

You can paint, veneer, or laminate plywood to fit your style.

Exterior plywood works for siding, roofs, and art projects. You can finish it in many ways. This helps match any design you want.

Plywood is a good deal. New machines and robots help make plywood better. They cut down on waste and keep prices low. You still get a strong and steady product. The table below shows how new technology helps with cost and quality:

Evidence Type | Description |

|---|---|

Automation and Digitization | Modern plywood plants use robotics and AI for precision cutting and quality control, reducing waste and improving consistency. |

Advancements in Adhesive Technology | The shift to eco-friendly adhesives enhances product safety and expands usage in moisture-exposed environments, impacting demand. |

Exterior plywood is smart to buy. It is strong, flexible, and not expensive. You save money but still get good quality.

You have learned what plywood is and why it is special. Plywood has thin wood layers glued together. The layers go in different directions. This makes plywood strong and steady. Modern factories use smart machines and tools. These help make plywood quickly and with good quality.

Key Aspect | Description |

|---|---|

Structure | Thin wood veneers glued in different grain directions |

Manufacturing | Machines help make plywood precise and eco-friendly |

Advantages | Strong, tough, flexible, resists water, and saves money |

When picking plywood, think about how thick it is. Also look at the core type and what you will use it for. Plywood works well for many projects. It is a good choice for lots of jobs.

You get strength from plywood because it has layers with grains running in different directions. This cross-grain structure helps plywood resist bending, splitting, and warping. You can trust plywood for projects that need extra support.

You can use plywood outside if you pick the right type. Look for exterior or marine plywood. These types resist water and weather. Always seal the edges and surfaces for longer life.

You should choose marine plywood for outdoor projects. It uses waterproof glue and high-quality veneers. This type stands up to rain and moisture. Many builders call it the best plywood for outdoor use.

You can use a sharp blade and cut slowly. Place painter's tape along the cut line. Support the plywood on both sides. This helps you get a clean edge with fewer splinters.

You can use plywood for furniture. Many types have low or no formaldehyde. Always check for safety labels. Plywood holds screws well and stays strong for years.